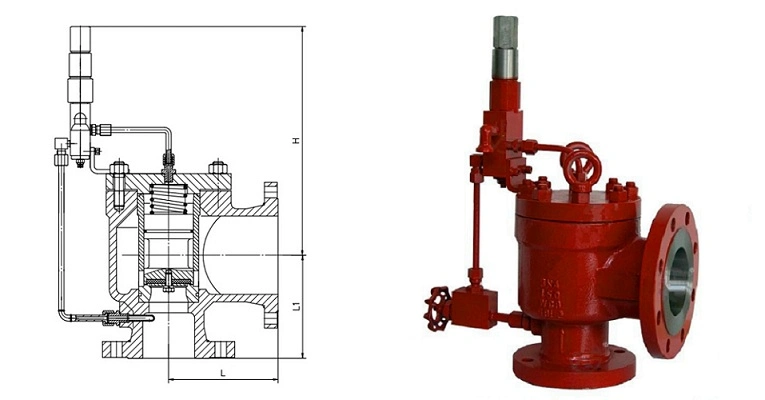

AEA Pilot Operated Safety Valve , with non-flowing pilot, is designed to provide the reliable overpressure protection you have come to expect in a cost effective package. This valve is well suited for gas, vapor, and many mixed phase services, including dirty and/or wet application. It is designed acc. to API 526,test according to API 527.This valve's type is A46C Pilot Operated Safety Valve.

Pilot operated safety valve, newly structured--is mainly applied to such trades as petroleum &

natural gas, chemistry, electric, metallurg & burning gas. It is the best super-pressure protecting equipment on pressure equipment, container or pipeline. It is mainly characteized by shifting direct function of spring to indirect function of quite valve. What's more, main valve, applying for sleeve piston & double sealed seat, is characterized by high precision of action, good recycling function fast turning back to seat, ability to high pressure leaking, long working time and security, together with read-justment on line, automatic turning back to seat after leaking again and again, tight closure, operating and maintaining convenience.

Standard Compliance:

-Design and Manufacture: API 520

-Face to Face(end to end): API 526

-Test and Inspection: API 527

Design Feature:

-Pilot Operated Safety Valve;

-Full lift safety valve;

-Conventional type, Standard safety valve for fluids and gas;

-Metal to metal seated;

- Load Type: Medium Controlled;

-Piping between the pilot and main valves is integrated into the cover to prevent damage and freezing

-Integrated Backflow Preventer as standard part

-Higher capacity than comparable size with extra orifices

-20% less installation space than competitors' comparable models

-Supplementary Loading System:

-Higher operating pressures are possible

-Closing pressure difference of up to -3 %; opening process is independent of back pressure

-Functional test and valve adjustment possible during operation

-Overpressure tolerance at a minimum of 1% with Pop Action

Main property specification

Code of throat diameter

Materials for main parts

Essential:

Valves are delivered at a set pressure, therefore when ordering

please confirm set pressure, medium and temperature

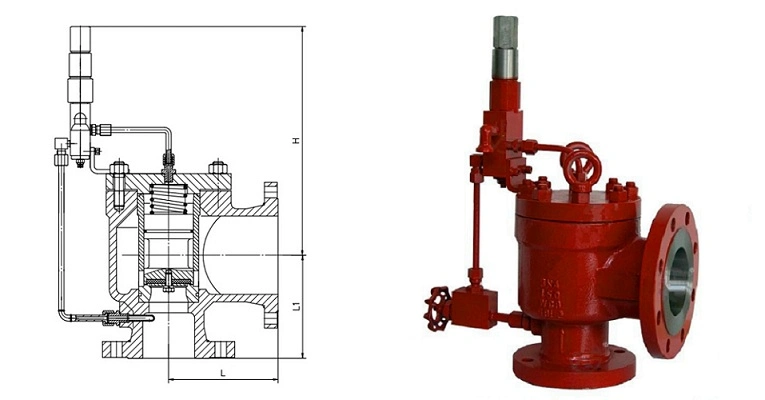

Pilot operated safety valve, newly structured--is mainly applied to such trades as petroleum &

natural gas, chemistry, electric, metallurg & burning gas. It is the best super-pressure protecting equipment on pressure equipment, container or pipeline. It is mainly characteized by shifting direct function of spring to indirect function of quite valve. What's more, main valve, applying for sleeve piston & double sealed seat, is characterized by high precision of action, good recycling function fast turning back to seat, ability to high pressure leaking, long working time and security, together with read-justment on line, automatic turning back to seat after leaking again and again, tight closure, operating and maintaining convenience.

Standard Compliance:

-Design and Manufacture: API 520

-Face to Face(end to end): API 526

-Test and Inspection: API 527

Design Feature:

-Pilot Operated Safety Valve;

-Full lift safety valve;

-Conventional type, Standard safety valve for fluids and gas;

-Metal to metal seated;

- Load Type: Medium Controlled;

-Piping between the pilot and main valves is integrated into the cover to prevent damage and freezing

-Integrated Backflow Preventer as standard part

-Higher capacity than comparable size with extra orifices

-20% less installation space than competitors' comparable models

-Supplementary Loading System:

-Higher operating pressures are possible

-Closing pressure difference of up to -3 %; opening process is independent of back pressure

-Functional test and valve adjustment possible during operation

-Overpressure tolerance at a minimum of 1% with Pop Action

Main property specification

| Normal Pressure | PN | 150 | 300 | 600 | 900 | 150 |

| Body strength | Ps(Mpa) | 3.0 | 7.5 | 15 | 22.5 | 37.5 |

| Set pressure | Pk(Mpa) | 0.1-2 | 1.6-5 | 3.2-10 | 8-25 | 10-25 |

| Seal pressure | Pm(Mpa) | 90%Pk | ||||

| Reseation pressure | Ph(Mpa) | ≥90%Pk | ||||

| Relieving Pressure | Pp(Mpa) | ≤1.1Pk | ||||

| Lift height | H(mm) | ≥1/4 d0 | ||||

| Appropriate temp. | ≤250ºC | |||||

| Appropriate Medium | Air, oil, water, corrosive medium | |||||

| Code | Diameter | Code | Diameter |

| D | 10 | L | 20 |

| E | 13 | M | 55 |

| F | 16 | N | 60 |

| G | 20.5 | P | 72 |

| H | 26 | Q | 96 |

| J | 33 | R | 115 |

| K | 40 | T | 148 |

| NO. | Name of part | Ax46Y/F AF46Y/F Material | KAx46Y/F Material |

| 1 | Body | WCB | WCB |

| 2 | Disc | 2Cr13/PTFE | 304/PTFE |

| 3 | Guide | 304 | 304 |

| 4 | Spring | 50CrVA | 50CrVA |

| 5 | O Ring | VITON | VITON |

| 6 | Bonnet | 25 | 25 |

| 7 | Pilot valve | Parts | |

Valves are delivered at a set pressure, therefore when ordering

please confirm set pressure, medium and temperature

| Why Choose us? |

| 1. Factory: |

| AEA VALVE, a specialist manufacturer, established since 2008 and professional production of industrial valves over 10 years. |

| 2. Regional Sale: |

| We provide specialized sales service refers to different kind of region all over the world. Each sales team member is good at the local language and well experienced to the responsible market. For example: Russian, German, Spanish, Japanese, etc. |

| 3. Low MOQ: |

| Our factory owns the casting company by itself. We are always ready for providing the sample and producing some small orders, in order to meet the business well. |

| 4. OEM or Customize: |

| OEM Service or Customized size is Available. |

| 5. We can make the products with the client's demand standard or the custom requirement. |

| 6. Complete Solution: |

| We are always ready to hear from you, be responding to your enquiry immediately. Our trade manager is always online for you. |

| 7. High Quality: |

| We have strict quality control system and amounts of testing equipments for different kind of valve, such as size, pressure, working environment etc. We are winning the market reputation with the time goes by. |

| 8. Quick Delivery: |

| We have the large stock for some hot products. |

| 9. Competitive Price: |

| 10. We are the manufacturing company which not only has our own manufacturing workshop, but the casting company as well. We provide the straight factory price and service to our customer. |

| 11. Quality control: |

| All the products are calibrated with real working condition, and tested before shipping as qualified product. |

| 12. Problem solve: |

| If you can't solve the problem in your local, please delivery the product to us, we will repair it and then back to you. |

| 13. Integrity: All the warranty and guarantee from us will be put into come true |

| 14.Online Service: any inquiry, please contact with email: . We will reply you within 12 hours. |