The products shown here is only to present the scope of our business activities. We can manufacture no standard parts according to your drawing or sample.

The products shown here is only to present the scope of our business activities. We can manufacture no standard parts according to your drawing or sample.Industrial Stainless Steel High Quality 2PC Spring Loaded Check Valve

A check valve, clack valve, non-return valve, reflux valve, retention valve or one-way valve is a valve that normally allows fluid (liquid or gas) to flow through it in only one direction.

Check valves are two-port valves, meaning they have two openings in the body, one for fluid to enter and the other for fluid to leave. There are various types of check valves used in a wide variety of applications. Check valves are often part of common household items. Although they are available in a wide range of sizes and costs, check valves generally are very small, simple, or inexpensive. Check valves work automatically and most are not controlled by a person or any external control; accordingly, most do not have any valve handle or stem. The bodies (external shells) of most check valves are made of plastic or metal.

An important concept in check valves is the cracking pressure which is the minimum differential upstream pressure between inlet and outlet at which the valve will operate. Typically the check valve is designed for and can therefore be specified for a specific cracking pressure.

Advantages of Stainless Steel Casting

- Sizes: 0.1 in to 24 in

- Weights: a few grams to more than 50 pounds

- Surface: very smooth finish

- Tight tolerances

- Reliable process controls and repeatability

- Design and casting versatility

- Efficient production

- Affordable tooling

- Material variety

Investment Casting vs. Die Casting

Investment casting has significantly cheaper tooling and is a more cost-effective option for lower quantity production runs. Additional benefits include a larger alloy selection and the ability to cast larger pieces.

Investment Casting vs. Sand Casting

Investment casting provides a better surface finish and allows for greater design flexibility including the ability to cast thinner walls, create tighter tolerances and create more intricate coring.

Investment Casting vs. Machining

Investment casting can significantly reduce the cost and lower the production time per piece. This is accomplished by producing near net shape parts, while greatly reducing the amount of material waste. In some instances, multiple fabricated parts can be produced as a single casting.

| Technology : | Investment Casting |

| Main Materials: | SS304, SS316,CF8M,CF8 |

| Working pressure: | PN16-PN63, 150LB-900LB |

| Applicable temperature: | -20~210 degree centigrade |

| Name | OEM stainless steel investment casting parts Material |

| Material | 304,306 ,2205stainless steel etc, |

| Designs | 1.As per the customer's drawings |

| 2.As per the customer's samples | |

| Surface treatment | 1. mirror polish |

| 2. passivation | |

| Service | OEM service available |

| Products | All kinds of stainless steel casting: include pipe fitting, ball valve, automotive parts,railroad parts, medical parts, marine parts, lighting parts,pump body, valve parts, architectural parts and furniture parts so on |

| Advantage | 1. More than 10 years experience in stainless steel casting; |

| 2. Near Tianjin Port and Tianjin Airport; | |

| 3. We provide: OEM stainless steel lost wax castings and OEM machining services for stainless steel lost wax castings. We have: CNC Machining, CNC turning, CNC Milling, 3D CMM Inspection and CNC Optical Inspection. We believe: on time, stable quality, just price, client confidentiality. | |

| 4. With samples and order: We can offer dimension report,material certification. | |

| Inspection: | 1.Dimension report |

| 2.Material certification | |

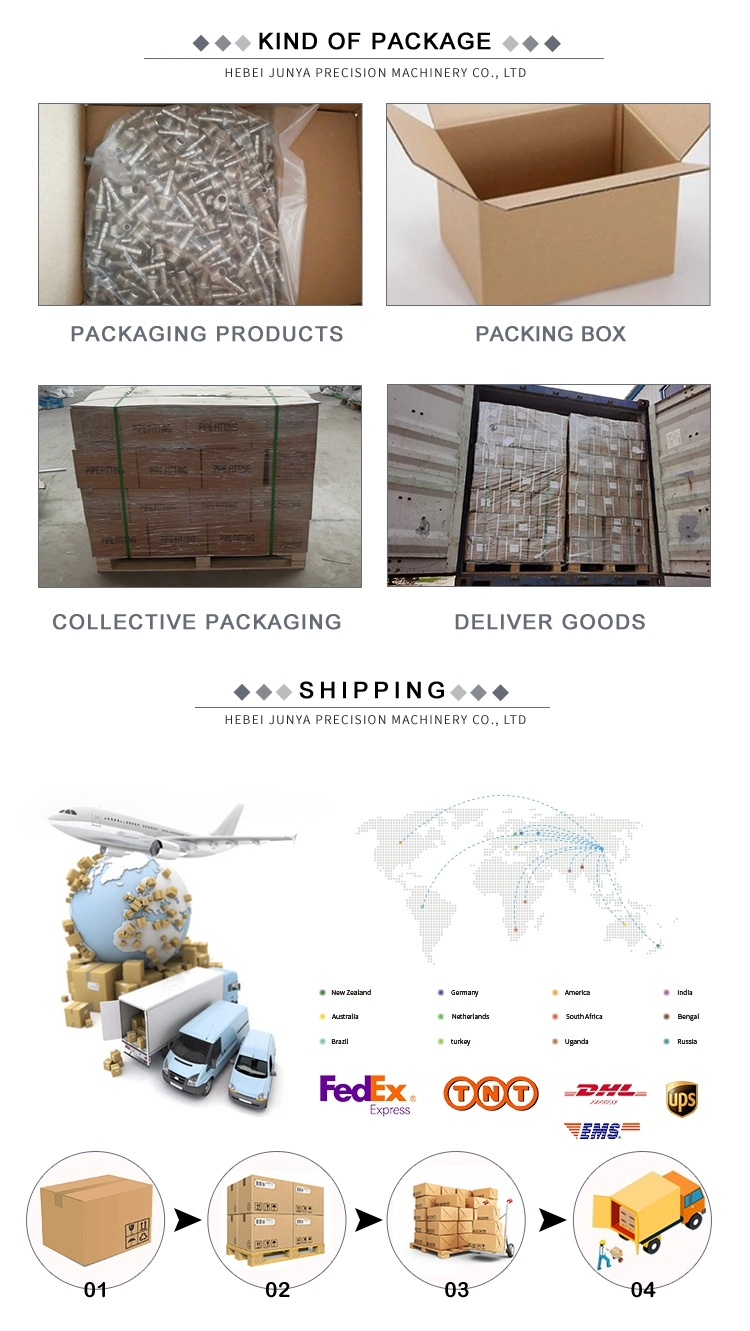

| Packing: | Export carton and fumigation wooden pall |

Casting Detail

Mainly Material | stainless steel, carbon steel, steel, aluminium, brass, bronze, copper |

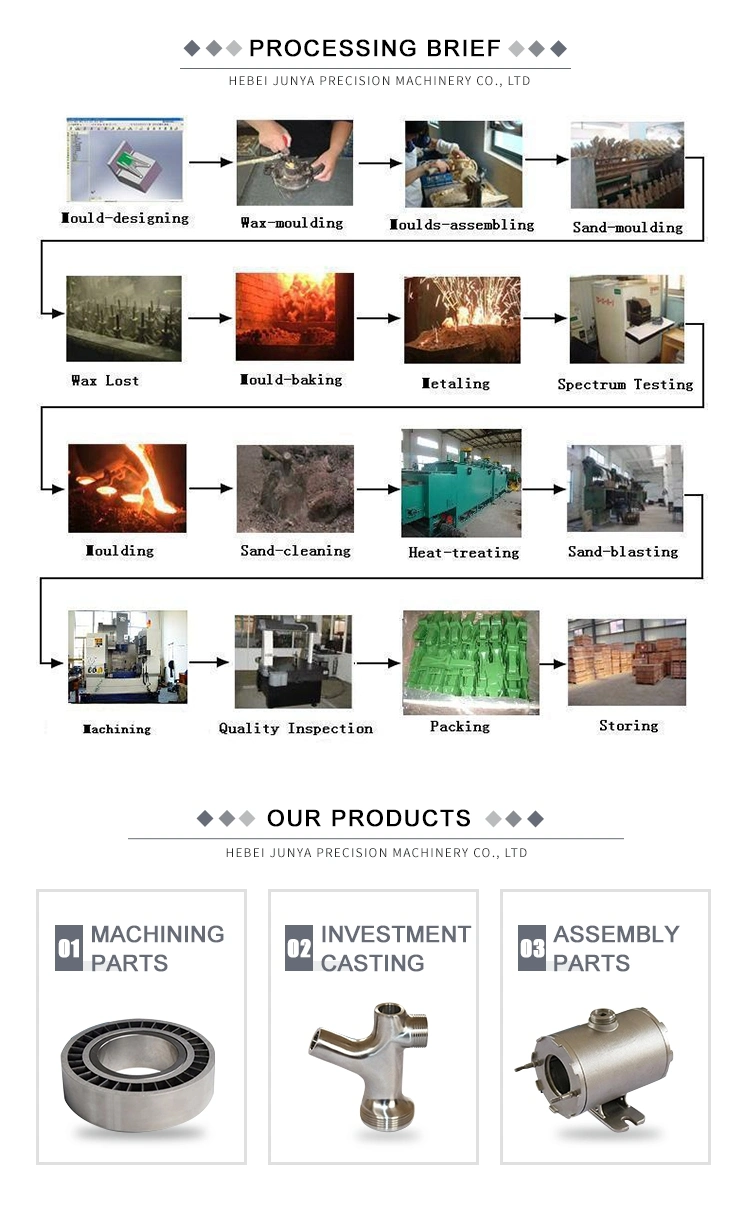

Process | investment casting, lost wax casting, silica sol casting. water glass casting, die casting |

Casting tolerance | CT4-CT6 (GB/T 6414),CT7-CT9 (GB/T 6414) |

Standard | AISI, ANSI, ASTM, JIS, GB, ISO, DIN |

Certificate | TS16949,SGS, ISO, or as your requirement to do test by the third party |

Machining | tapping, milling, grinding, drilling, cnc machining |

Tolerance | +/-0.02mm or as drawing requirement |

Surface treatment | polishing,mirror polishing, electrogalvanizing, sandblasting, shot blasting |

Heat treatment | quchenging and tempering, annealing, normalizing |

Casting Roughness | Ra 1.6-Ra12.5 |

Application

• Agricultural equipment | • Armament | • Automobile industry | • Computing equipment |

• Medical / dental instruments | • Measuring instruments | • Miscellaneous equipment | • Pharmaceutical industry |

• Orthopedic implants | • Safety equipment | • Petrochemical industry | • Industrial valves |

•Fixing and movable equipment | • Sanitary fittings | • General machinery | • Pumps and general connections |

• Food and beverage processing | • Instrumentation equipment | • Pharmaceutical industry | • Textile equipment |

Quality Control

1) Checking the details before the production line operated

2) Have full inspection and routing inspection during mass production---In process quality control(IPQC)

3) Checking the goods after they are finished---- Final quality control(FQC)

4) Checking the goods after they are finished-----Outgoing quality control(OQC)

*Our wax casting product processed by 79 steps with high standard and 100% inspection. Along with the power of our advanced machine, quality is something you do not need to worry about.

Hebei Junya Precision Machinery Co. Ltd is a high-tech enterprise combine designing, tooling developing, casting, machining, surface treatment, inspection, sales and service all together. Founded in 2017, located in Huanghua, Hebei. Junya now covers an area of more than 5000 square meters.

With a massive research & development environment, Junya utilized market-leading technology and introduced various of advanced equipment to ensure the stringent quality in production.

Under a powerful management team, the company has growing to the group with more than 100 employees. Product offerings range from Stainless Steel Pipe Fitting, Quick Joint, Ball Valve, Check Valve, to Marine Hardware and Auto Parts. The material are 304, 304L, 316, 316L, SF8M, WCB, 1.4408, etc.

-Quality- -Creativity- -Consistency-

These words are Junya slogan, and also philosophy that drives the company to offer the superior service you are looking for.

1) Design assistance and full engineering support .

2) Professional at OEM & ODM parts .

3) Excellent after sales service.

4) Advanced machine tools, CAD/CAM programming software.

5) Prototype machining capabilities.

6) Strict quality control standards with a highly qualified inspection department .

7) Continually upgrading and advancing our equipment to remain competitive .

8) Small quality is also available.

FAQ:

Q1: How long is your delivery time?

A:Delivery time is depends on the total quantity of order. Normally, sample can be delivered within 15 days.

Q2: Do you provide samples? Is it free or extra?

A:Yes, we could offer sample for free, and we can pay for the model as well, but the clients has to pay for the shipping cost.

Q3: What is the MOQ of your products?

A:It depends on the category of order.

Q4: Where is your factory?

A:Our factory located in Hebei province, close to Tianjin seaport.

Q5:What does your company need to submit a quotation?

A:Drawing or Sample, together with relevant information, such as Quantity, Weight, Material.

Q6:What we do not have a drawing?

A:We can duplicate your sample and make drawing for your confirmation.